The design parameters which affect the. In this paper an integrated methodology tailoring all the different parameters for the design and sizing of a small-scale fluidized bed gasification plants is presented.

Bubbling Fluidized Bed Reactor Chemical Engineering World

The reactor consists of a gas distributor an internal cyclone with solids recycle through a dipleg and a heat exchanger.

. Under these conditions the reactor is usually referred to as a. Bed reactor fluidization gas line. The fluidized bed designed and fabricated in this work consists of the drying column fluidized plate the inlet and outlet unit the heating unit and the fan.

Bubbling fluidized bed technology was first used for gasification by Winkler in 1921 and work on bubbling fluidized bed combustion BFBC technology started in the 1950s several years prior to that on CFBC. This report describes the design testing and initial operation of a plug-flow fluidized bed reactor. Although CFBC plants are more widely used BFBC designs are still sold although for more specialized applications.

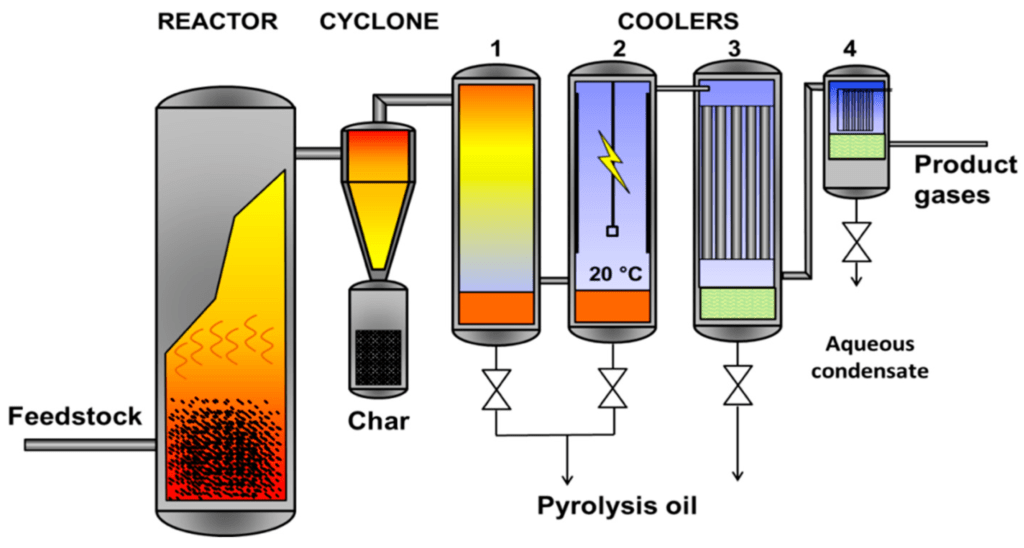

Flow through Fluidized Beds - 1 SCHWING. Output gas line 9. This is shown in Fig.

A laboratory scale fluidized bed reactor was designed and fabricated successfully. A 0-15 m x 015 m x 73 m tall circulating bed reactor with solids returned via an L-val e has been. Feeding system gas flow line 7.

A bed section b freeboard section and c conical closure section with inlet cone. MP-PIC method is extensively used for simulating BFB CFB spouted bed and dual fluidized bed reactors with coal biomass and their blends. Using this methodology a 40 kWth biomass gasification reactor was.

The evaluation considered the drying time and temperature in achieving quality. Provided the reactor diameter is sufficiently large only a few design parameters are independent of scale eg. Reprinted with permission from 79.

DESIGN AND CONSTRUCTION OF A FLUIDIZED BED by Robert Ryan Mota Bachelor of Science California State Polytechnic University Pomona 2010 A Thesis. Coal gasification Cement clinker production. Bubbling fluidized bed reactor system.

Bed reactor cooling gas line 11. In particular for reactive fluidized beds the mass transfer of reactant gas from the bubble phase to the dense phase is highly scale-dependent. Cracking of Hydrocarbons Fluid Catalytic Cracking etc.

Mod-01 Lec-36 Fluidized Bed Reactor Design Part I Lec 23. For the catalytic cracking of petroleum naphthas to form gasoline blends for example the virtues of the fluidized-bed reactor drove its competitors from the market. For no bubbles a packed bed 95 conversion As bubbles grow in size from 8 to 16 to 32 cm conversion decreases to 84 to 59 and to 32.

I will send you videos. The IDAES Bubbling Fluidized Bed Reactor BFBR model represents a unit operation where two material streams a solid phase and a gas phase pass through a linear vessel while undergoing chemical reaction s. The relation Johstone 13.

Contain summary of the seminar report. Thus larger bubbles give more gas by passing and thus lowers the. Gas sampling valve 10.

Correlations and models for the prediction of the minimum fluidization and bubbling conditions the expansion and voidage of fluidized beds the size and velocity of gas bubbles are thus presented. Youve Already won. When this begins to happen the bubbling and agitation of the solids are still present and this is known as the region of fast fluidization and the bed is a fast-fluidized bed.

21 2013 15 likes 11331 views Akshay Patil Download Now Download to read offline Description Transcript Its a seminars presentation. Umf and umb 9. Part B presents a synthesis of the literature available on selected subjects of primary importance to the design of fluidized bed reactors.

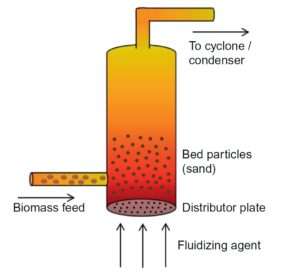

The BFBR model is represented as a 1-D axially discretized model with two phases gas and solid and two regions bubble and emulsion. A fluidized bed reactor FBR is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In this type of reactor a fluid gas or liquid is passed through a solid granular material usually a catalyst at high enough speeds to suspend the solid and cause it to behave as though it were a fluid.

Bubbling fluidized bed reactor Nov. At velocities beyond this region the particles are well apart and the particles are merely carried along with the gas stream. Industrial Applications of Fluidized Bed Reactor Acrylonitrile by the Sohio Process.

Fluidized Bed Reactor GEMINI NOVEMBER Theyre buying time. Abstract The circulating fluidized bed reactor has unique qualities which differentiate it from other gas-solid contactors and make it promising for a wide range of reaction. Statler College of Engineering and.

This presentation contains 2 videos if you are facing any problem regarding the video please contact me. Methodology for designing a bubbling fluidized bed biomass gasification reactor. The fluidized-bed reactor has the ability to process large volumes of fluid.

Fluidization occurs when small solid particles are suspended in an upward-flowing stream of fluid as shown in Figure R1231. A typical dense phase bubbling bed reactor design. Applying the methodology the design was carried out and the reactor was built and tested obtaining feedback to improve the design process.

The Where ρp and ρf represent the density of bed particles and fluid fluidization behavior of bubbling fluidized beds BFB is best respectively H depth of bed g acceleration due to gravity and described by two phase theory of fluidization by Toomey and voidage ε in a vessel of cross sectional area A. The reactor consists of three sections. The freeboard section of the vessel is expanded and the heat exchanger may also function as a baffle.

Inputs The syngas is produced using as a primary fuel biomass that is mixed with a gasifying agent Air. The drying efficiency and the amount of moisture reduced per time and. Masten 9 also claims that the bed density is scale-independent.

MP-PIC method has higher computational efficiency than CFD-DEM but the prediction accuracy on. Compressed air tank 3. The reactor is designed to overcome the problem of nonuniform residence times of particles.

Methanol to gasoline and olefin processes. Fluidized Bed Principle Fluidized bed OTK 1 - Fixed and Fluidized Bed ANSYS FLUENT Tutorial - Fluidized Bed Mod-01 Lec-37 Fluidized Bed Reactor Design Part IILecture 21.

Bubbling Fluidized Bed An Overview Sciencedirect Topics

Schematic Diagram Of A Bubbling Fluidized Bed Reactor Download Scientific Diagram

Bubbling Fluidized Bed An Overview Sciencedirect Topics

Bubbling Fluidized Bed An Overview Sciencedirect Topics

Bubbling Fluidized Bed An Overview Sciencedirect Topics

Bubbling Fluidized Bed Reactor Chemical Engineering World

Bubbling Fluidized Bed Reactor With An Electrostatic Precipitator Download Scientific Diagram

Two Phase Model To Present The Bubbling In Fluidized Bed Reactor Download Scientific Diagram

0 comments

Post a Comment